Wireless Sensor Networks for Train Predictive Maintenance

TRX R6 used as WSN Gateway for train predictive maintenance on EU-funded SCOTT Project

Reducing Operating Costs is a key focus for the Rail industry. Leveraging train Predictive Maintenance algorithms allows rail operators to take trains out of service in advance of a costly failure which can impact the train service.

However, adding the sensors needed to rolling stock is a costly process, particularly where wired sensors are being used. Inevitably, trains have to be taken out of service for the installations which impact on any benefits that may be gained.

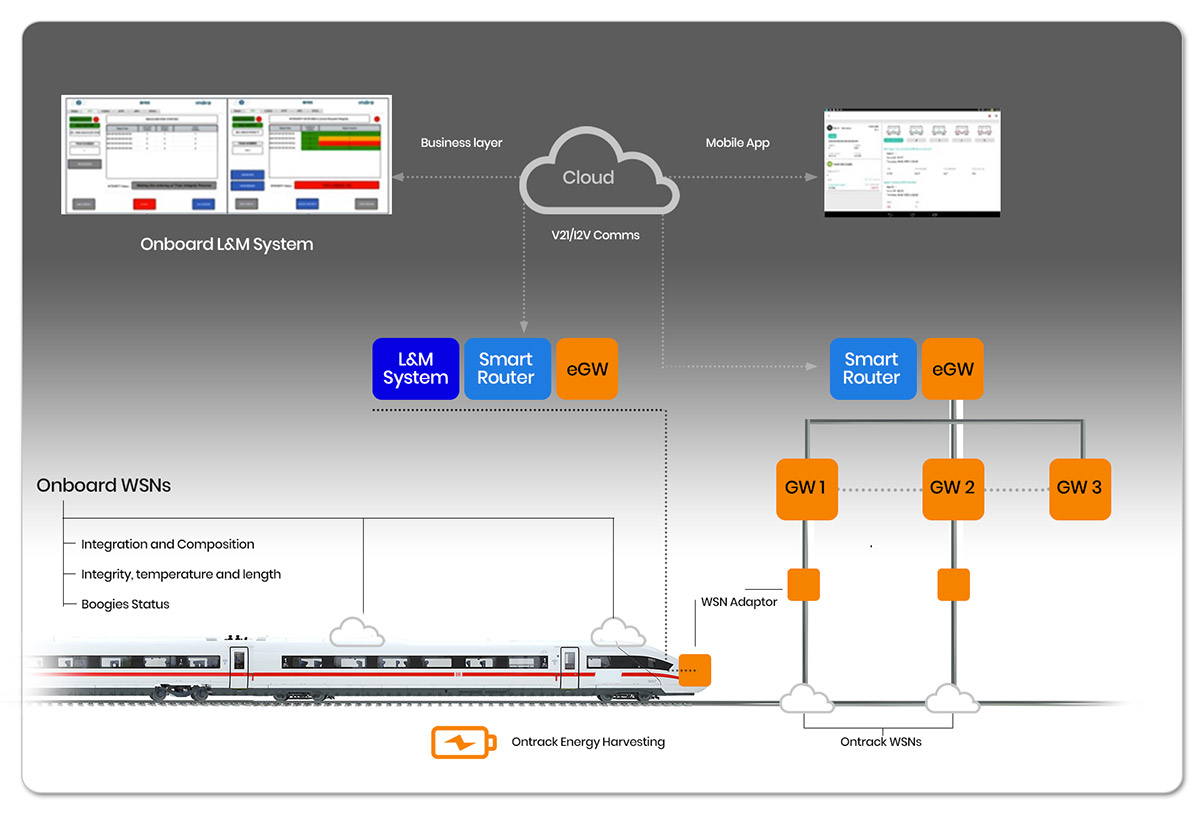

The EU-funded SCOTT program has devised an Autonomous Wireless Network (AWN) system for both On-Board and On-Track devices, which provides trusted wireless connectivity between them and Centralized Systems (TMS, Cloud Services).

The AWN will enhance operations and train predictive maintenance as a first step for future services, at low cost and easy installation.

For this project, the TRX R6 has been selected as the onboard gateway thanks to its multiple interface options for the wireless sensor network and the multiple 3G/4G modems available for V2X connectivity. In addition to this, some other partners have developed methods for uplink data rate estimation and interface selection that is only possible thanks to the TRX R6 open platform which can host third party applications.

This has resulted in the following benefits:

- Reduction of the maintenance and installation cost due to the wireless solution (vs wired).

- AWN as a Rail digitalization enabler to improve Rail Operation and Maintenance redundant on Passenger trips and Rail Network capacity.

- Improvement of coordination in maintenance work and location at shunting yard facilities.

Continue reading TRX stories

« AI/ML at the edge Extending in-station Wi-Fi service to trains »