In this blog, we delve into the engineering and science of the Voyager chassis and transit case and into the level of protection offered to end users in extreme environments.

The Voyager 8 and 8+ chassis and associated transit cases are rated for IP67 compliance. IP67 is a specification that’s part of an international rating system for ingress protection to determine how well an electrical enclosure can withstand penetration or ingress by dust and moisture.

IP67 Compliance

As with all electronics, water and dust are the nemesis. For mission-critical systems to be survivable, they require protection, and in the case of the Voyager family, this starts with the rugged transit case.

The first mechanical challenge to overcome is accessing the IT systems in the protective shell. Therefore, there has to be an opening in the Voyager transit case, which means two large openings. As we all know, water has an innate ability to find its way into the tightest of openings. Therefore, the Voyager transit case and lids are fitted with an O-ring seal around both lids, forming an airtight barrier when locked in place.

However, air tightness creates a secondary challenge, especially where air pressure changes, e.g. during flight. A vacuum could cause the lids to become forcibly stuck. To circumvent the issue, the Voyager transit case is fitted with a pressure-equalizing valve to equalize the air pressure on the inside with the outside.

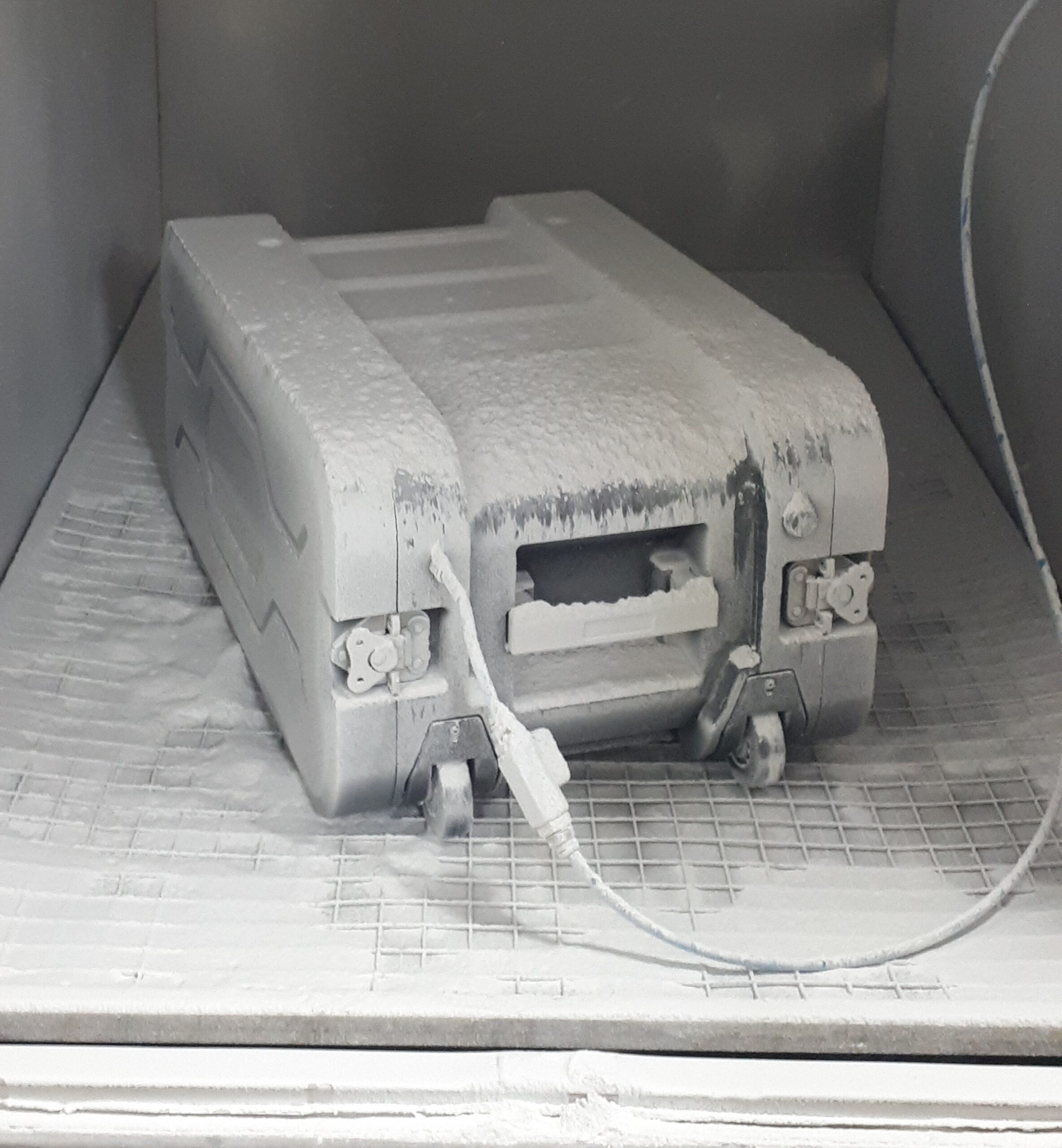

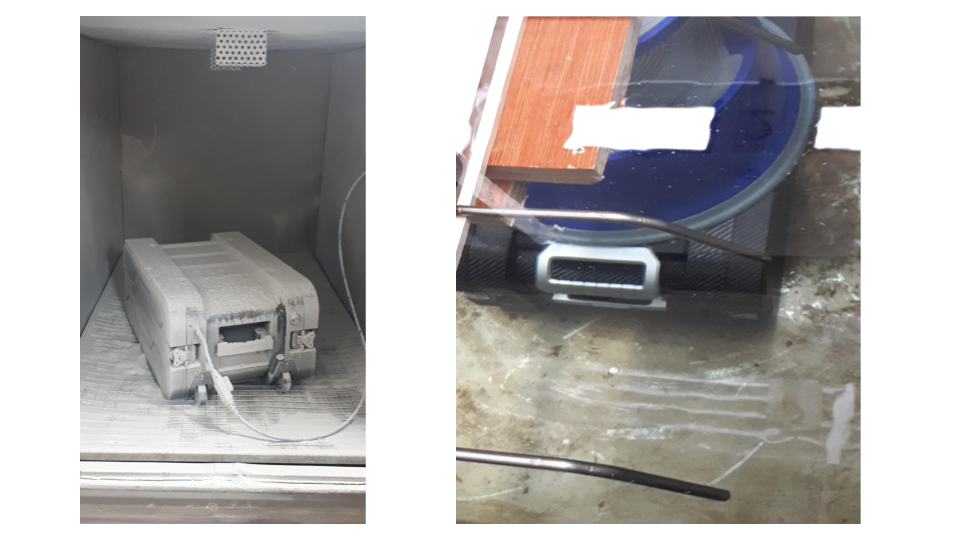

Furthermore, to prove its mechanical prowess, the solution is independently tested and verified by certified laboratories.

(note the water inlet at the bottom of the right handside image)

Sometimes words are not enough. Check out the short video below to see the testing Klas’ rugged chassis goes through.

Rugged not ruggedized!

Material selection and its use are vital to delivering a survivable chassis. For example, the Voyager roll-on/off case is constructed from aerospace-grade, multidirectional carbon fiber.

The multidirectional configuration allows for tailored reinforcement, providing enhanced performance compared to traditional unidirectional carbon fiber and hardened plastics:

- High Strength-to-Weight Ratio: Surpassing that of traditional materials like steel or aluminum.

- Directional Strength and Stiffness: High structural performance to meet the load requirements of the integrated rack, power, Voyager modules, radio brackets, and radios.

- Corrosion Resistant: Unlike metals, carbon fiber is inherently corrosion-resistant, making it suitable for harsh environments at the Tactical Edge.

- Fatigue Resistant: Carbon fiber exhibits exceptional fatigue resistance and is ideal for repetitive loading and cyclic stresses, ensuring prolonged durability and reliability.

Learn more about the Voyager chassis

Voyager chassis, right-sized for all deployment requirements – https://www.klasgroup.com/government/products/#chassis

Voyager, the only TrueTactical™ chassis – https://www.klasgroup.com/voyager-the-only-truetactical-chassis-for-the-edge/

Voyager 8+ the smart edge chassis – https://www.klasgroup.com/voyager-8-the-smart-edge-chassis/